We offer you 100% custom-made service Inquiry

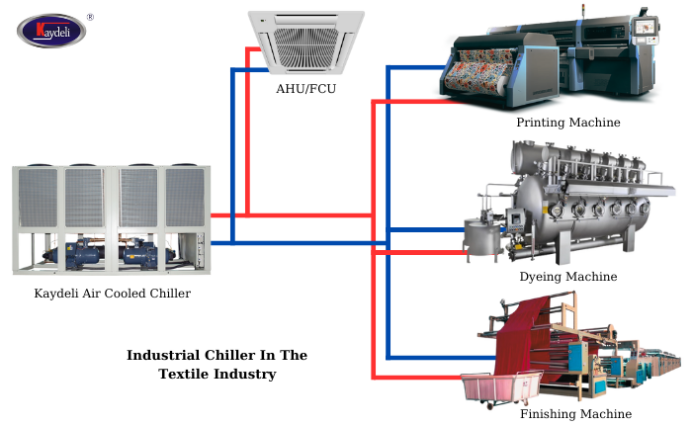

In the textile industry, industrial chillers play a crucial role in ensuring high-quality products. These machines are responsible for cooling water used in various textile processes such as dyeing, printing, and finishing. In this article, we will explore how industrial chillers work and their importance in the textile industry.

Industrial chillers are designed to remove heat from a liquid or gas in a closed loop system. They use a refrigeration cycle to cool water, which is then circulated through the textile production process. The refrigeration cycle works by compressing a refrigerant gas, which raises its temperature. The hot gas is then cooled and condensed back into a liquid, releasing heat in the process. The liquid refrigerant is then expanded, causing it to cool down significantly. This cold liquid is then used to cool the water in the textile production process.

There are two types of industrial chillers: air-cooled and water-cooled. Air-cooled chillers use ambient air to cool the refrigerant, while water-cooled chillers use water to cool the refrigerant. Water-cooled chillers are more efficient than air-cooled chillers, but they require a constant supply of water.

Industrial chillers play a critical role in the textile industry by ensuring that water used in various processes is at the right temperature. Here are some of the reasons why industrial chillers are important in the textile industry:

Dyeing is the process of adding color to textiles. This process requires hot water to be circulated through the fabric to ensure that the dye penetrates evenly. Industrial chillers are used to cool down the water after it has been heated to the required temperature. This ensures that the fabric is not damaged and that the dye penetrates evenly.

Printing is the process of adding designs or patterns to textiles. This process requires hot water to be circulated through the fabric to ensure that the ink adheres properly. Industrial chillers are used to cool down the water after it has been heated to the required temperature. This ensures that the fabric is not damaged and that the ink adheres properly.

Finishing is the process of improving the appearance and texture of textiles. This process requires hot water to be circulated through the fabric to ensure that it is properly finished. Industrial chillers are used to cool down the water after it has been heated to the required temperature. This ensures that the fabric is not damaged and that it is properly finished.

Industrial chillers are designed to be energy efficient. They use less energy than traditional cooling methods such as air conditioning. This means that they can help textile manufacturers save money on their energy bills.

Industrial chillers help ensure that textile products are of high quality. By maintaining a consistent temperature throughout the production process, industrial chillers help prevent damage to fabrics and ensure that dyes, inks, and finishes adhere properly.

Industrial chillers play a critical role in ensuring high-quality textile products. They help maintain a consistent temperature throughout the production process, preventing damage to fabrics and ensuring that dyes, inks, and finishes adhere properly. Industrial chillers are also energy efficient, helping textile manufacturers save money on their energy bills.

By continuing to use the site you agree to our privacy policy Terms and Conditions.