We offer you 100% custom-made service Inquiry

A glycol chiller is an essential component in the brewing industry as it helps maintain the ideal temperature for the brewing process. The brewing process involves a complex series of chemical reactions that are temperature-dependent. As such, it is crucial to keep the temperature within a specific range to ensure that the beer quality is consistent and of high quality.

Glycol chillers are used to regulate the temperature of the glycol solution, which is then circulated through the cooling jackets of the fermenters and bright tanks. The glycol solution absorbs the heat generated during fermentation and transfers it to the chiller, where it is expelled into the atmosphere. This process prevents the beer from overheating, which can lead to undesirable flavors and aromas.

Here is how it works:

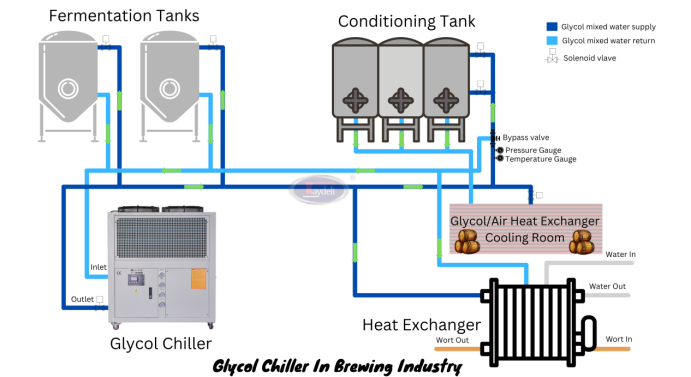

Glycol chillers work by circulating a glycol solution through a closed loop system that includes the fermentation tanks, conditioning tanks, and heat exchangers. The glycol solution absorbs the heat generated during the fermentation process and transfers it to the chiller, where it is expelled into the atmosphere.

The glycol solution is pumped through cooling jackets that surround the fermentation and conditioning tanks. As the glycol solution circulates through the jackets, it absorbs the heat generated by the yeast during fermentation. The heated glycol solution is then pumped back to the chiller, where it is cooled down before being recirculated through the cooling jackets.

Glycol chillers can also provide cooling for the storage room by circulating cool glycol solution through air handling units. This process helps maintain a consistent temperature in the storage room, preventing spoilage of the beer.

In addition to cooling the fermentation and conditioning tanks, glycol chillers can also be used in heat exchangers to chill the beer. The beer is passed through a heat exchanger that is cooled by the glycol solution. As the beer passes through the heat exchanger, it is rapidly cooled down to the desired temperature before being transferred to the conditioning tanks.

Glycol chillers are also used in other industries such as food processing, pharmaceuticals, and HVAC systems. In the food processing industry, glycol chillers are used to maintain the temperature of food products during production. For example, they are used to cool chocolate during the tempering process or to keep ice cream mixtures at a specific temperature during production.

In the pharmaceutical industry, glycol chillers are used to maintain the temperature of vaccines and other medications. Vaccines require strict temperature control during storage and transportation to ensure their efficacy. Glycol chillers are used to keep the vaccines at a specific temperature range to prevent degradation and ensure their effectiveness.

In HVAC systems, glycol chillers are used to cool water that is circulated through air handling units to regulate the temperature of a building. This process helps maintain a comfortable indoor environment for occupants.

In conclusion, glycol chillers are essential components in various industries, including the brewing industry. They help maintain the ideal temperature for different processes, ensuring consistent quality and preventing spoilage. Other industries such as food processing, pharmaceuticals, and HVAC systems also rely on glycol chillers for temperature regulation.

By continuing to use the site you agree to our privacy policy Terms and Conditions.