We offer you 100% custom-made service Inquiry

Air Handling Units (AHUs) are an important component of HVAC systems that are responsible for circulating air throughout a building. In order to maintain a comfortable and healthy indoor environment, it's important that the air is kept at the right temperature and humidity levels. This is where Kaydeli AHU chillers come in - they are designed to provide reliable cooling solutions for AHUs, ensuring that the air supplied to a building is comfortable and healthy.

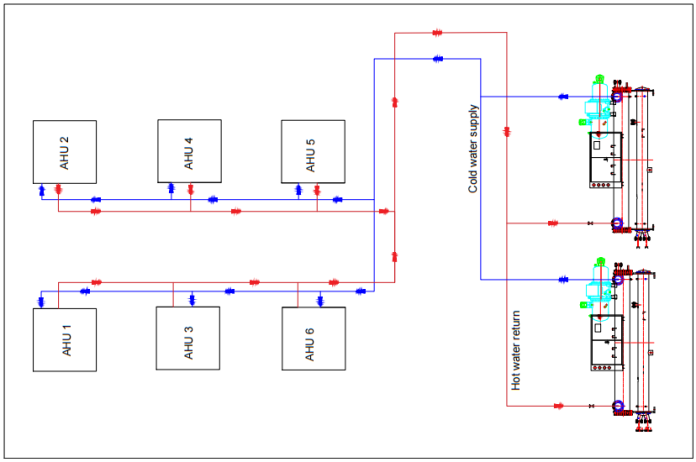

A Kaydeli AHU chiller works by circulating chilled water through the AHU. The chiller contains a refrigeration cycle that is used to cool the water, which is then circulated through the AHU's cooling coil. The cooling coil removes heat and moisture from the air that is passed over it, resulting in cool, dry air that is then supplied to the building's HVAC system.

The refrigeration cycle in a Kaydeli AHU chiller typically includes four key components: a compressor, a condenser, an expansion valve, and an evaporator. The compressor is responsible for compressing the refrigerant gas, which raises its temperature and pressure. The high-pressure gas is then passed through a condenser, which removes heat from the gas and converts it into a high-pressure liquid.

The high-pressure liquid is then passed through an expansion valve, which reduces its pressure and temperature. The low-pressure liquid is then passed through an evaporator, where it absorbs heat from the water that is circulated through the chiller. The heat absorbed by the refrigerant is then carried away by the compressor, which starts the cycle over again.

chiller's microcomputer controller is responsible for regulating the temperature of the chilled water that is circulated through the AHU. The controller monitors the temperature of the chilled water and adjusts the operation of the chiller's components as needed to maintain the desired temperature. The controller also includes safety features such as high and low-pressure protection, anti-freezing protection, and power-off protection to ensure safe and reliable operation.

The whole mechanism of a Kaydeli AHU chiller in an AHU involves several key components that work together to provide reliable cooling. The chiller itself is typically housed in a mechanical room or basement and is connected to the AHU by a series of pipes that circulate the chilled water.

The chiller's compressor is typically driven by an electric motor and is responsible for compressing the refrigerant gas. The refrigerant gas is then passed through the condenser, which removes heat from the gas and converts it into a high-pressure liquid.

The high-pressure liquid is then passed through an expansion valve, which reduces its pressure and temperature. The low-pressure liquid is then passed through the evaporator, which absorbs heat from the water that is circulated through the chiller. The heat absorbed by the refrigerant is then carried away by the compressor, which starts the cycle over again.

The chiller's microcomputer controller is responsible for monitoring and regulating the temperature of the chilled water that is circulated through the AHU. The controller adjusts the operation of the chiller's components as needed to maintain the desired temperature, and includes safety features to ensure safe and reliable operation.

Overall, a Kaydeli AHU chiller is a reliable and efficient solution for cooling air in an AHU. By providing chilled water that is circulated through the AHU's cooling coil, the chiller helps to maintain comfortable and healthy indoor environments for a wide range of applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.