We offer you 100% custom-made service Inquiry

In the new energy lithium battery industry, kaydeli chiller has been maintaining close cooperation with industry companies, and is responsible for the production and manufacture of new energy companies, providing constant temperature and constant flow circulating cooling water control, improving product quality, and reducing equipment high temperature. It is Important industrial equipment that is indispensable in new energy production and manufacturing.

Inner Mongolia OptimumNano Energy Battery Co., Ltd. is a new energy company engaged in the research and development and operation of lithium batteries in the early stage. During the first phase of its construction, it is necessary to purchase a batch of chillers to cool down the Sanding machine in the workshop. The required cooling capacity is estimated to be around 880KW.

Due to the large refrigeration capacity, considering that the procurement of equipment for the new project is proceeding normally, the customer found several chiller manufacturers through various channels, and compared and selected the cooling solutions for the sander workshop, including the three-way parallel cycle refrigeration system design provided by Kaydeli. Each channel can be used for independent refrigeration or joint refrigeration, and the cooperative refrigeration can complete the cooling task according to the setting.

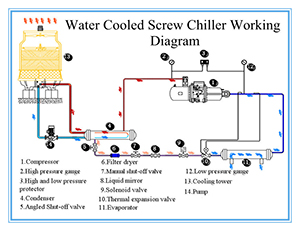

The plan includes three sets of kaydeli KDS-100SLA water-cooled screw chillers, and a single unit can provide 300KW cooling capacity, and also includes independent insulation water tanks, refrigerated circulating water pumps, cooling water towers, valves and other refrigeration accessories. Under normal circumstances, the three sets of refrigeration systems work together to achieve a cooling capacity of 900KW, and the refrigeration conditions can be automatically adjusted according to the production load throughout the year.

In a single-channel refrigeration cycle, the temperature of the chilled water is continuously reduced by the internal circulation of the chiller refrigerant, and is transported by the circulating water pump to the water tank. The low temperature area of the water tank enters the low temperature chilled water through the pipe into the pipe jacket of the sander, and the high temperature generated by the work take it back to the cooling water pipe and enter the high temperature area of the water tank.

When the temperature of the heat preservation water tank is too high, it will trigger the water tank switch to restart a new round of refrigeration, continuously reduce the temperature to the set temperature, meet the predetermined cooling target of the workshop, and ensure the safety of equipment and stable production.

By continuing to use the site you agree to our privacy policy Terms and Conditions.