Printed Circuit Boards (PCBs) are critical components in electronics, serving as the structural and electrical foundation for connecting electronic elements. They are widely used in consumer electronics, telecommunications, computing, automotive systems, industrial controls, medical devices, defense, and aerospace, forming the backbone of modern electronics.

The PCB manufacturing industry is highly energy-intensive, consuming significant amounts of water, electricity, and gas. Amid declining orders, price competition, and shrinking profit margins, many manufacturers are prioritizing cost reduction and efficiency gains through energy-saving initiatives to maintain competitiveness.

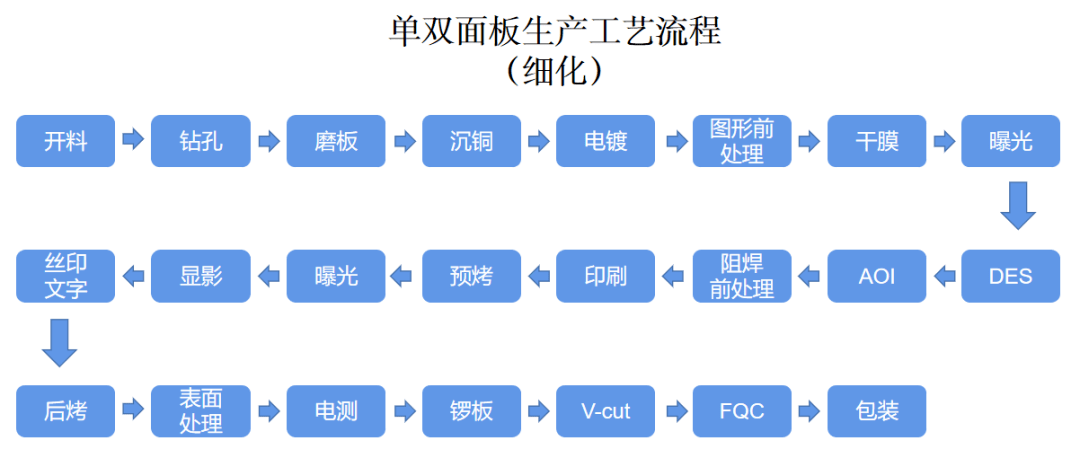

PCB production involves multiple processes such as imaging, etching, drilling, plating, multilayer lamination, solder masking, and electroplating. Precise temperature control is critical for equipment and chemical solutions across these stages:

Degreasing: Temperature must be maintained at 60–65°C.

Drilling: Chilled water temperature required at 15–20°C.

Electroplating: Chilled water temperature controlled to 25–30°C. Elevated temperatures risk destabilizing chemical copper baths, degrading electroless copper plating quality.

Many PCB factories still rely on energy-intensive electric heating or steam boilers for process and HVAC heating, which are inefficient and pose safety risks. Kaydeli PCB-specific industrial high-temperature heat pump hybrid systems offer a sustainable alternative. These systems extract waste heat from process cooling water to generate hot water while supplying chilled water for cooling, achieving full utilization of thermal energy and improving the system’s overall Coefficient of Performance (COP).

A PCB manufacturer in Dongguan, China, had long depended on an outdated chiller plant to meet its production cooling demands. As production scaled up, the system’s inefficiencies—poor energy performance, mismatched configurations, and high operating costs—became untenable.

Kaydeli implemented a comprehensive retrofit based on high-efficiency chiller plant design principles, including:

Optimized chiller configuration: Strategic mix of chiller capacities and integration of permanent magnet variable-frequency pumps.

Advanced piping design: Minimized hydraulic resistance and energy loss.

Low-water-consumption cooling towers: Reduced makeup water usage.

Intelligent control system: Real-time monitoring and adaptive adjustments.

Following a detailed assessment of production conditions and thermal load calculations, Kaydeli deployed its PCB-specific water-cooled screw chiller units paired with insulated buffer tanks. Post-retrofit, the client reported over 50% reduction in energy consumption.

The screw chillers deliver stable cooling water to high-heat processes such as drilling, cutting, etching, and soldering. A precision temperature control system dynamically adjusts outputs to maintain consistent cooling performance.

[Kaydeli PCB-Optimized Magnetic-Bearing Chiller (Heat Pump) Unit]

The screw chillers’ high Energy Efficiency Ratio (EER) and stable operation make them ideal for PCB environments with heavy cooling demands. Compared to traditional systems, these units significantly reduce power consumption.

The retrofitted system adapts cooling capacity based on seasonal climate and production fluctuations. This flexibility minimizes water and energy waste while lowering labor and maintenance costs, enhancing operational efficiency.

[Kaydeli PCB-Specific Industrial High-Temperature Heat Pump]

Kaydeli PCB dedicated chiller is suitable for drilling machines, laser cutting machines, exposure machines/developers, etching equipment, laminating machines, UV curing equipment, etc. By providing stable low-temperature cooling water, it effectively reduces the operating temperature of equipment in the PCB production line and improves the stability and service life of the equipment.

At the same time, the chiller can also help the equipment maintain high precision and high efficiency, thereby improving the quality and production efficiency of PCB products.

This case study underscores the viability of advanced thermal management solutions in transforming energy-intensive industries. By integrating intelligent design, cutting-edge equipment, and waste heat recovery, Kaydeli demonstrates how PCB manufacturers can achieve sustainability without compromising productivity or quality.

By continuing to use the site you agree to our privacy policy Terms and Conditions.