Before we jump into the installation process of water cooled chiller let's know something about the water-cooled chiller and its working principle.

Water cooled chiller:

A water-cooled chiller is a cooling system that is driven by water. In details,

The diluted solution absorbs the coolant while the heat is absorbed by the cooling water. The diluted solution of coolant and absorbent flows through a heat exchanger to the generator where it is heated.

The coolant vaporizes out of the solution, condenses, and is sent out for cooling again.

Water-cooled chillers feature a water-cooled condenser connected with a cooling tower. They have commonly been used for medium and large installations that have a sufficient water supply. Water-cooled chillers can produce a more constant performance for commercial and industrial air conditioning because of the relative independence from fluctuations in the ambient temperature. Water-cooled chillers range in size from small 20-ton capacity models to several thousand-ton models that cool the world’s largest facilities such as airports, shopping malls, and other facilities.

A typical water-cooled chiller uses recirculating condenser water from a cooling tower to condense the refrigerant. A water-cooled chiller contains a refrigerant dependent on the entering condenser water temperature (and flow rate), which functions in relation to the ambient wet-bulb temperature. Since the wet-bulb temperature is always lower than the dry-bulb temperature, the refrigerant condensing temperature (and pressure) in a water-cooled chiller can often operate significantly lower than in an air-cooled chiller. Thus, water-cooled chillers can operate more efficiently.

Water-cooled chillers typically reside indoors in an environment protected from the elements. Hence, the water-cooled chiller can offer a longer lifespan. Water-cooled chillers typically represent the only option for larger installations. The additional cooling tower system will require additional installation expense and maintenance as compared to air-cooled chillers.

Application field:

They're commonly used for large and medium facilities with consistent and efficient water supply. For example, restaurants, industrial plants, hotels, sporting arenas, and healthcare facilities. Moreover, water-cooled chiller systems have a cooling tower, thus they are more energy efficient than air-cooled chillers.

Cooling tower:

A cooling tower is a device that uses water as a circulating coolant to absorb heat from a system and discharge it into the atmosphere to reduce the temperature of the water; its cooling is to use water and air to flow in contact with each other to exchange cold and heat to produce steam, and steam volatilizes to take away heat to achieve evaporation The principle of heat dissipation, convection heat transfer, and radiation heat transfer to dissipate the waste heat generated in the industry or refrigeration and air conditioning to reduce the water temperature evaporative heat sink to ensure the normal operation of the system.

How to connect and install water cooled chiller with a cooling tower.

The installation process of an industrial water-cooled chiller is not as hard as it seems, it can be installed by following a few simple steps.

Connections with the cooling tower.

Water inlet and water outlet pipe recognization.

Pump connections.

Pressure gauge, rubber soft joint, and filters connection.

Connecting with the water-cooled chiller.

Water tank connection (Optional)

The picture reference and descriptions are given below.

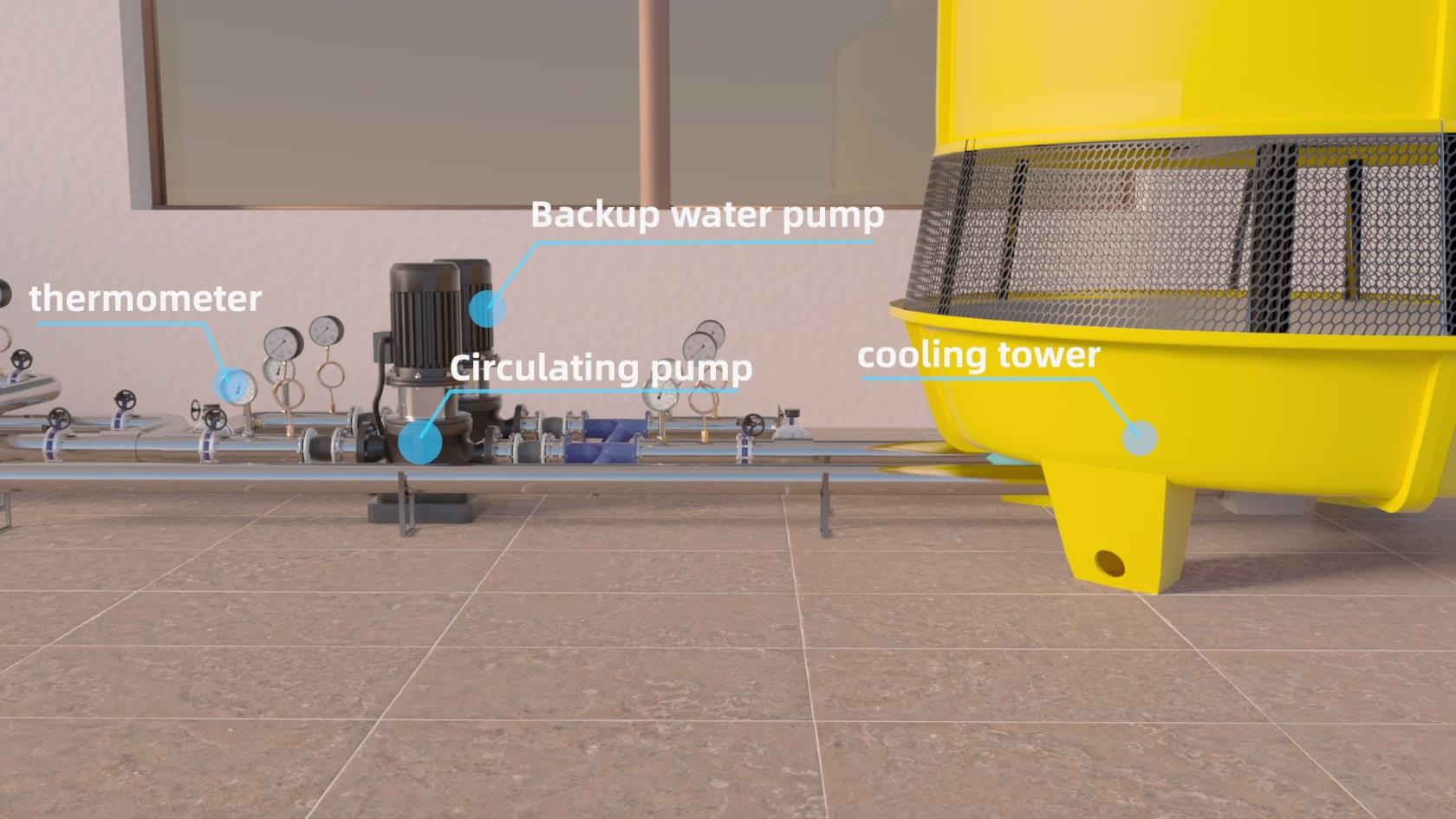

Connection with the cooling tower

Assemble the cooling tower and find the connection spot (Inlet and outlet), connect it with the water inlet and outlet pipe.

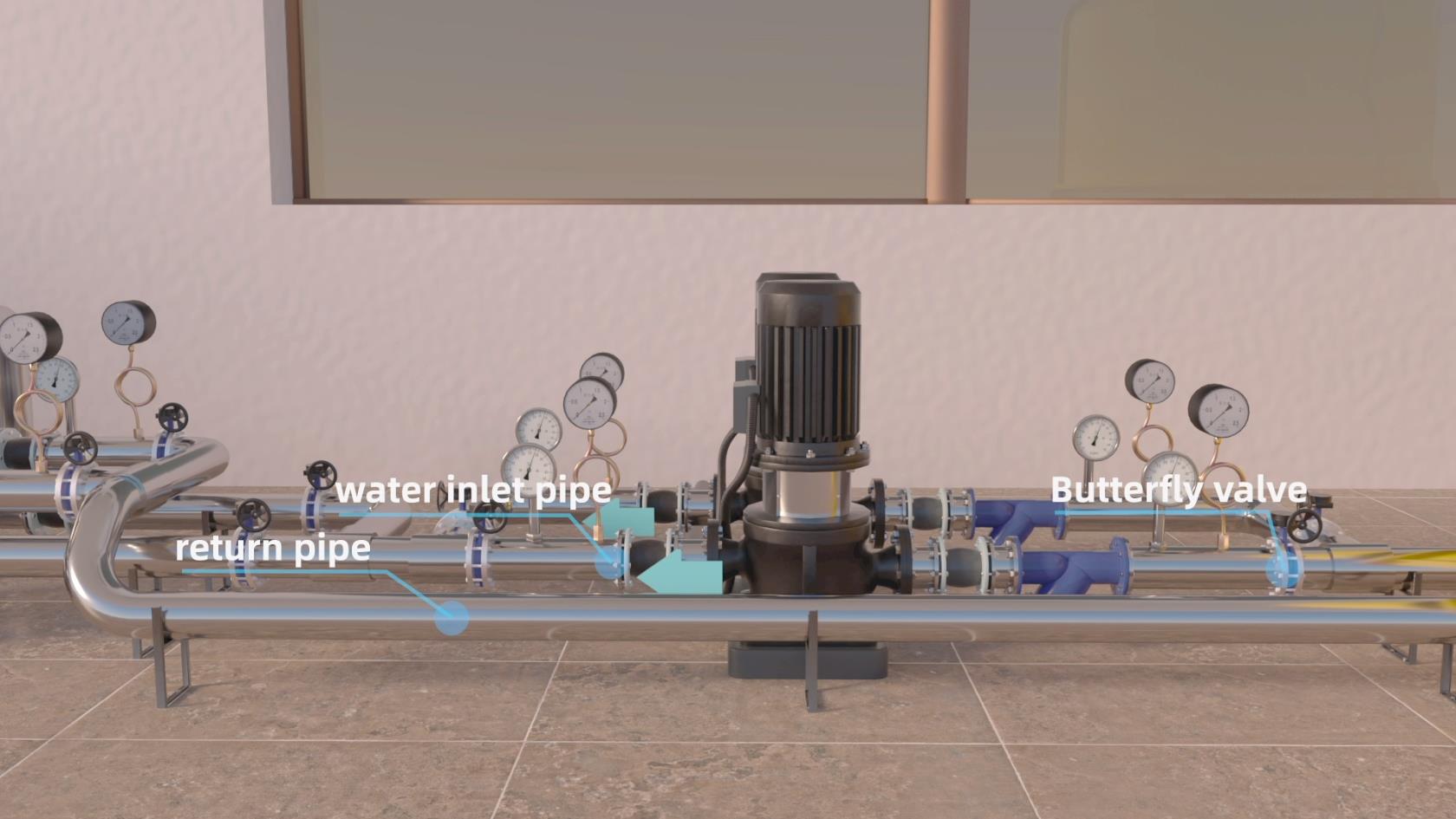

Water inlet and water outlet pipe recognization, pump, Pressure gauge, rubber soft joint, and filters connection.

Here are the water inlet pipe and water outlet pipe indicated in this picture.

For a water-cooled chiller unit, there could be more than a single pump, that needs to install and connect correctly.

There are two types of connections such as primary loop and secondary loop.

The primary loop uses a constant speed pump to circulate the working fluid (water). The secondary loop uses a variable speed pump to manipulate the flow of the fluid such that the cooling coil demand is satisfied.

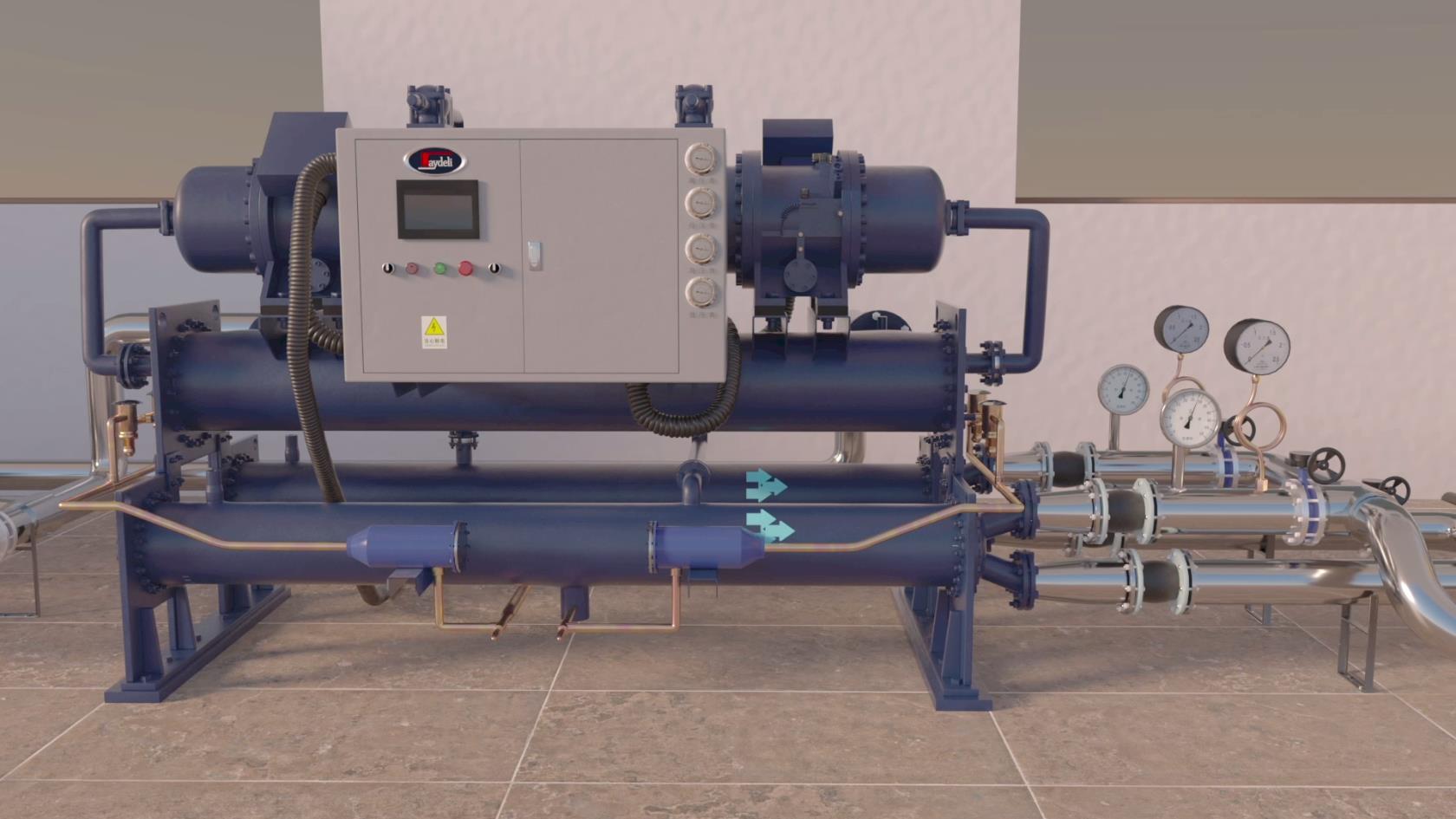

Here is the connection with the chiller inlet and outlet pipe.

By following the steps consultation or support from the manufacturer or associated companies, it's easy to install a water-cooled chiller with several pumps and a cooling tower.

The installation could be more specified and clear if the project plan is provided.

Contact our professionals to get a smooth guide

Feel free to contact us to get help for your project from the professionals.

By continuing to use the site you agree to our privacy policy Terms and Conditions.