KWB series industrial chiller is mainly applied in Plastic & Rubber industry; it can accurately control the molding temperature and shorten the molding cycle, increase the product quality and improve the production efficiency. They are also widely used in Metal working, Mechanical & Engineering, Chemical & Pharmaceutical, Food & Beverage, Laser, Electronics industry, Textile, Electroplate, Semi-conductor testing, Water jet, Vacuum coating, Construction and Military industry.

Features:

¨ opted world famous brand compressors and high efficiency condenser and evaporator, ensure high cooling efficiency, low energy consumption, low noise and long service life.

¨ Chilled water temperature range 5℃ to 35℃.

¨ R22 charged, CFC free type R407C, R410A, R404A, R134A for option, high cooling efficiency.

¨ Over sized evaporator and condenser ensure the chiller unit running under 45C high ambient temperature.

¨ Microcomputer control system offering accurate temperature stability within ±1℃.

¨ Low noise and big volume air blower.

¨ Standard equipped Iron pump, stainless steel or high lift pump for option.

¨ Multi-protection devices ensure the chiller unit running safely.

¨ The innovative evaporator-in-tank configuration ensures a stey water temperature offered, as the evaporator also cools the tank itself, reduces ambient heat gain, and increases the efficiency.

¨ KWB water cooled industrial chiller opted shell and tube condenser, features speed heat dissipation and high cooling efficiency, it is good to be used in High ambient temperature area with abundant water.

¨ Power supply: 1PH 220V/50HZ-----1/2HP to 2HP

3PH 380V/415V 50HZ-----3HP to 60HP

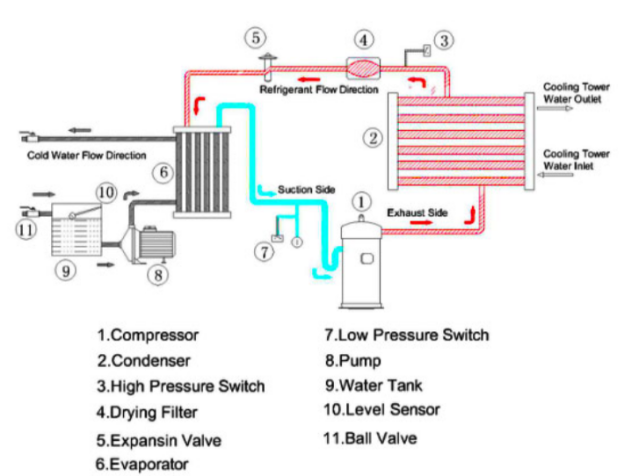

Water Cooled Water Chiller operation diagram

Specifications(cooling capacity from 9.5KW to 186.5KW for scroll type chiller, screw chiller could contact us):

Water-cooled Industrial Chillers Units Specifications | ||||||||||

Model | KWB | KWB | KWB | KWB | KWB | KWB | KWB | |||

cooling capacity | kW | 9.5 | 16.3 | 23.5 | 31.9 | 40.3 | 48.2 | 63.6 | ||

50HZ/60HZ | 11.8 | 19.6 | 28.2 | 38.3 | 48.4 | 57.8 | 76.3 | |||

kcal/h | 8,170 | 14,018 | 20,210 | 27,430 | 34,650 | 41,460 | 54,690 | |||

50HZ/60HZ | 9,804 | 16,822 | 24,252 | 32,916 | 41,580 | 49,752 | 65,628 | |||

Input power | kW | 2.4 | 4.1 | 6.0 | 8.1 | 10.3 | 12.4 | 16.5 | ||

Chilled fluid flow | m3/h | 1.6 | 2.6 | 4.3 | 5.5 | 6.9 | 8.2 | 10.8 | ||

1.9 | 3.1 | 5.2 | 6.6 | 8.3 | 9.8 | 13.0 | ||||

cooling fluid flow | m3/h | 2.0 | 3.2 | 5.4 | 6.8 | 8.6 | 10.3 | 13.9 | ||

2.4 | 3.8 | 6.5 | 8.2 | 10.3 | 12.4 | 16.7 | ||||

Power supply voltage | 3PH-380V-50HZ(200V/220V/415V 50HZ/60HZ) | |||||||||

Compressor | Mode | Hermetic scroll type (Piston) | ||||||||

Start-up mode | Sequential start | |||||||||

Power(kw) | 2.3 | 3.8 | 5.6 | 7.5 | 9.4 | 11.3 | 15.0 | |||

Refrigerant | Mode | R-22(R407c/R134a) | ||||||||

Control mode | Expansion valve | |||||||||

Filling amount(kg) | 1.5 | 2.5 | 4.0 | 5.0 | 6.2 | 7.5 | 10.5 | |||

Evaporator | Mode | Shell and Tube(Water tank with coil) | ||||||||

Pipe | B | PT 1" | PT 1-1/2" | PT 2" | ||||||

Condenser | Mode | Shell and Tube | ||||||||

Pipe | B | PT 1" | PT 1-1/2" | PT 2" | PT 2-1/2" | |||||

Tank volume | L | 60 | 60 | 130 | 130 | 130 | 180 | 180 | ||

pump power | kW | 0.37 | 0.75 | 0.75 | 1.1 | 1.1 | 1.5 | 1.5 | ||

Protective device | Compressor overheating,over current,high and low pressure,over temperature,flow switch,phase sequence,phase-missing,exhaust overheating,anti-freezing. | |||||||||

Dimension | L | mm | 890 | 1000 | 1300 | 1300 | 1400 | 1550 | 1700 | |

w | mm | 500 | 600 | 630 | 630 | 700 | 700 | 900 | ||

H | mm | 840 | 1080 | 1300 | 1300 | 1300 | 1340 | 1330 | ||

Weigh | kg | 130 | 180 | 310 | 330 | 400 | 520 | 630 | ||

Mode | KWB | KWB | KWB | KWB | KWB | KWB | KWB | |||

cooling capacity | kW | 78.2 | 95.2 | 108.3 | 125.1 | 139.8 | 155.3 | 186.5 | ||

50HZ/60HZ | 93.8 | 114.2 | 130.0 | 150.1 | 167.8 | 186.4 | 223.8 | |||

kcal/h | 67,250 | 81,870 | 93,130 | 107,580 | 120,230 | 133,560 | 160,390 | |||

50HZ/60HZ | 80,700 | 98,244 | 111,756 | 129,096 | 144,276 | 160,272 | 192,468 | |||

Input power | kW | 20.2 | 24.6 | 28.3 | 32.2 | 36.5 | 40.3 | 48.5 | ||

Chilled fluid flow | m3/h | 13.6 | 16.0 | 18.8 | 21.2 | 24.1 | 26.5 | 31.8 | ||

16.3 | 19.2 | 22.6 | 25.4 | 28.9 | 31.8 | 38.2 | ||||

cooling fluid flow | m3/h | 17.2 | 20.5 | 24.0 | 27.3 | 30.8 | 34.2 | 40.8 | ||

20.6 | 24.6 | 28.8 | 32.8 | 37.0 | 41.0 | 49.0 | ||||

Power supply voltage | 3PH-380V-50HZ(200V/220V/415V 50HZ/60HZ) | |||||||||

Compressor | Mode | Hermetic scroll type (Piston) | ||||||||

Start-up mode | Sequential start | |||||||||

Power(kw) | 18.8 | 22.5 | 26.3 | 30.0 | 33.8 | 37.5 | 45.0 | |||

Refrigerant | Mode | R-22(R407c/R134a) | ||||||||

Control mode | Expansion valve | |||||||||

Filling amount(kg) | 12.5 | 15.0 | 17.5 | 20.2 | 22.5 | 25.0 | 30.0 | |||

Evaporator | Mode | Shell and Tube(Water tank with coil | ||||||||

Pipe | B | PT 2-1/2" | PT 3" | |||||||

Condenser | Mode | Shell and Tube | ||||||||

Pipe | B | PT 2-1/2" | PT 3" | |||||||

Tank volume | L | 180 | 220 | 220 | 220 | 280 | 280 | 280 | ||

pump power | kW | 1.5 | 2.2 | 2.2 | 2.2 | 3.0 | 3.0 | 3.0 | ||

Protective device | Compressor overheating,over current,high and low pressure,over temperature,flow switch,phase sequence,phase-missing,exhaust overheating,anti-freezing. | |||||||||

Dimension | L | mm | 1700 | 2100 | 2100 | 2100 | 2100 | 2100 | 2400 | |

w | mm | 900 | 900 | 900 | 1100 | 1100 | 1100 | 1100 | ||

H | mm | 1330 | 1380 | 1380 | 1430 | 1450 | 1450 | 1450 | ||

Weight | kg | 680 | 890 | 1000 | 1090 | 1300 | 1430 | 1600 | ||

Note: 1. Parameters of the above specifications:Inlet/outlet chilled fluid temperature:12℃/7℃ Inlet/outlet cooling water temperature:30℃/35℃ | ||||||||||

2.The above specifications are subject to change without notice, if there are special requirements, please ask for specifications before ordering. | ||||||||||

Actual KWB-015SA photoes shot in our factory:

|  |

|  |

Our main product:

Chiller, Freezer, TCU, Screw Chiller, Low-temperature freezer, chiller, heat recovery unit, environmental chiller, laser chiller, cold oil machine, mold temperature chiller, low-temperature freezer, plant central air conditioning projects, and so on so forth.

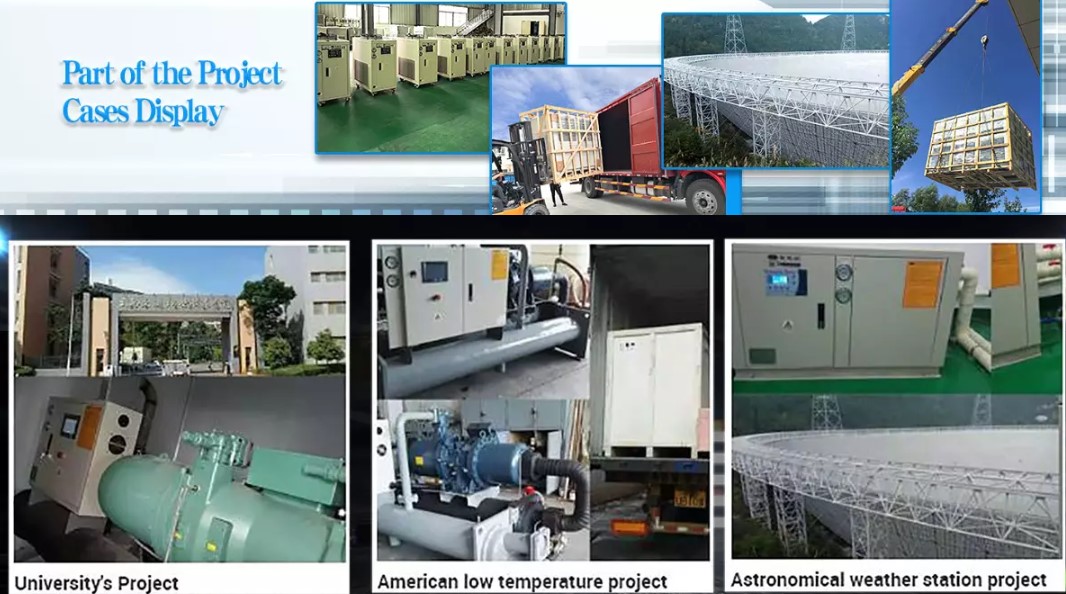

Some projects show:

Contact Us:

Kaydeli located in shenzhen and dongguan city, welcomed to visit us!

Kaydeli industrial Park

Kaydeli open China factory in 2002.

With rapid development, Kaydeli establish 2 factory bases located in: Shenzhen city &Dongguan city now.

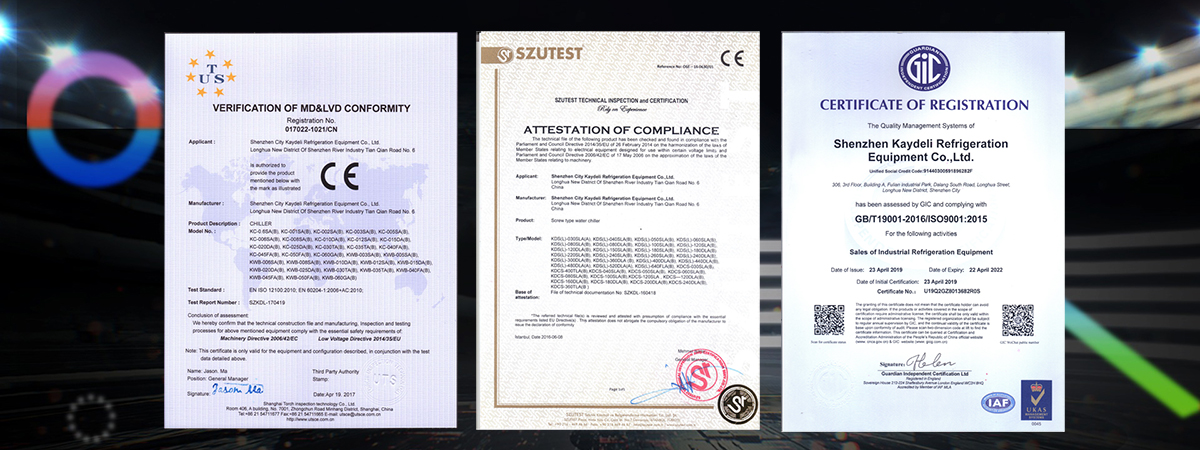

Certification: ISO9001:2016, SGS,Interk auditted factory, CE Certification,China Quality Brand, GTS,

ilac-MRA, CNAS, CMA testing report, 5A after-sales service certification.

Due to healthy development,Kaydeli Brand Chiller Is Top 10 in China Water Cooling Industry Now.

Exhibition:

Core Advantage:

Shenzhen Kaydeli Refrigeration Equipment Co., Ltd. was established in Shenzhen, due to business development, we establish manufacturing base in Dongguan city, which we has two factories to do production and researching now. We mainly manufacture and research chillers, TCU, screw chillers, low-temperature freezer, and has experiences in manufacturing high-end chiller equipment. We operate the brand of “Kaydeli”. We are the only Company with China's well-known trademarks, China top brands and China export branded enterprises of refrigeration industry in China. Our refrigeration technology is well-known in China, we can customize various types of models (from temperature -180℃ to -5℃). Our company has ISO international quality system certification, products have CE (PED) certification, and obtained many patents for energy-saving products.

Certification:

Service Principle: Everything for the user, quick response

Kaydeli is dedicated to providing the following services to our customers:

1. Provide telephone consult for chiller’s performance and technical parameters, online consultation;

2. Provide a complete refrigeration solution or product selection for your production process;

3. Provide other supporting facilities required for refrigeration equipment;

4. Provide financial estimates for refrigeration systems and economic analysis of refrigeration systems;

5. Provide solutions for the freezing station, central air conditioning, combined cold storage project;

6. Provide design plans for cooling which do advanced process design or construction drawing design ;

7. Provide instructions when you are in the process of using the product;

8. Provide the latest developments of the product;

9. Provide installation and commissioning service or guidance;

10. Provide automatic control equipment for refrigeration or cooling systems, also contract to total control cooling equipments;

11. Design and manufacture refrigeration equipment or devices according to your requirements, or jointly develop special refrigeration equipment or devices;

12. Repair and maintenance during the use of the equipment, also contract to overhaul the equipment;

13. Track the production condition of your order.

FAQ:

Q1. Do you have any MOQ limit for chiller?

A: Low MOQ, 1pc for sample checking is available.

Q2. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea, we could ship the standard chiller in 3-15 days, customized chiller in 25-35working days.

Q3. Do you offer guarantee for the products?

A: Yeas, we offer 12 months warranty to our products.

Q4: Where the application?

A: Our products have been widely used in many industries, like Plastic machinery,PCB Machinery, New Energy industry,Pharmaceutical Industry, Petrochemical industry, Environmental protection industry and other industries.

Q5: Are your products can be customized?

A: Yes. Also welcomed to customized non-standard products, can achieve to -180 degree Celsius and EXDIIBT4 Explosion-proof chiller.

Q6: Whats your payment term?

A: International term-30% deposit for production, 70% balance before shipment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.