Air-cooled screw chillers are widely used in industrial refrigeration projects of different scales in various industries, such as factory equipment cooling and chemical industry, printing presses, planting, reactors, fermentation tanks, hospitals, refrigeration and refrigeration. KDCS screw chillers are our company The experience of designing and producing water chillers, combined with the latest technological development, has concentrated on research, design and development of chillers. The product keeps up with the development trend of the times, adhering to the design concept of "high efficiency, reliability, energy saving, and environmental protection" to provide users with an excellent refrigeration equipment.

Features:

Well Known Brand Compressor

¨ Unit adopts Germany BITZER or Taiwan HANBELL brand semi-hermetic screw compressor. The latest 5 to 6 patented screw rotor profile with excellent efficiency.

¨ Adjustable infinite or closely stepped capacity control features energy-efficient, stable and quiet running.

¨ Most advanced patented highest precision manufacturing process.

¨ Built-in full intelligent monitoring and protection including thermal motor temperature monitoring, phase sequence monitoring, manual reset lock-out, and oil temperature sensor.

¨ Wide range of refrigerants for options, including R134a, R407c, and R22(R404a, R507c upon request).

Micro-programming Control System

¨ Industrial PLC centralized control combined with compressor capacity control system, precisely monitor.

¨ Integrated protection for low temperature, high/low pressure, anti-freezing, phase missing, anti-phase, overload, motor over temperature, oil differential, flow switch, and start-up latency.

¨ Optional operation language, menu leading, unit running state easy to adjust.

Easy Installation, Reliable Running

¨ Closely stepped start-up, minimize impact to electricity.

¨ Steady and safe running, low vibration, easy for installation.

¨ Compact structure, less space demand and light in weight, easy for transport and installation.

¨ Completely wired, inspected, and tested pre-delivery, saving installation time and cost.

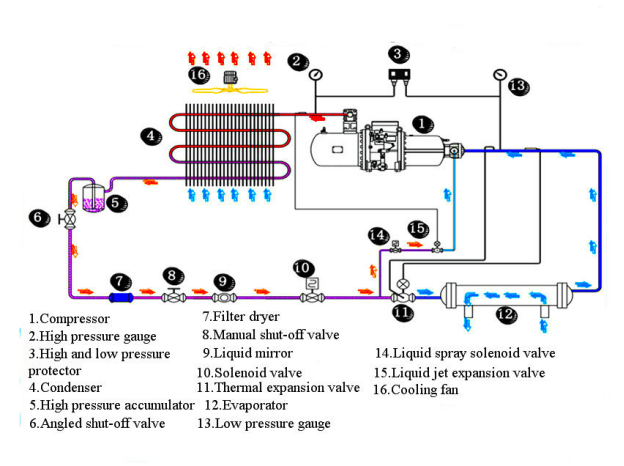

Air-cooled water chiller operation diagram:

Specifications(cooling capacity from 119KW to 1156KW for scroll type chiller, screw chiller could contact us):

| ||||||||||

Model | KDCS | KDCS | KDCS | KDCS | KDCS | KDCS | KDCS | |||

Power supply voltage | 3Φ-50Hz-380V | |||||||||

cooling capacity | KW | 119.0 | 148.0 | 188.0 | 236.0 | 299.0 | 366.0 | 398.0 | ||

kcal/h | 102,340 | 127,280 | 161,680 | 202,960 | 257,140 | 314,760 | 342,280 | |||

Input power | KW | 38.7 | 48.2 | 58.0 | 71.0 | 92.9 | 116.3 | 121.4 | ||

Chilled fluid flow | m3/h | 20.0 | 26.0 | 32.0 | 35.0 | 50.0 | 60.0 | 76.0 | ||

Compressor | Type | Semi-Hermetic screw type | ||||||||

Start-up mode | 0,33,66,100 | 0,25,50,75,100 | ||||||||

Power(kW) | 34.3 | 43.8 | 53.6 | 66.5 | 84.1 | 107.5 | 112.6 | |||

Refrigerant | Type | R-22 | ||||||||

Control mode | Thermostatic Expansion valve | |||||||||

Filling amount(kg) | 21.0 | 26.0 | 31.0 | 35.0 | 49.0 | 58.0 | 78.0 | |||

Evaporator | Type | Shell and Tube | ||||||||

Pipe | B | PT3" | PT 4" | PT 4" | PT5" | |||||

Condenser | Type | High-efficient air-cooled inner threaded copper-tubing aluminum fin type | ||||||||

Cooling fan | Type | Low noise outer rotor fan | ||||||||

Air volume(CMM) | 940 | 940 | 940 | 940 | 1790 | 1790 | 1790 | |||

Power(kW) | 2.2*2 | 2.2*2 | 1.1*4 | 1.5*4 | 1.5*6 | 2.2*6 | 2.2*8 | |||

Protective device | Compressor overheating, over current, high and low pressure, over temperature, flow switch, phase sequence,phase-missing, exhaust overheating,anti-freezing protection. | |||||||||

Dimension | L | mm | 2300 | 2500 | 2200 | 2200 | 3050 | 4400 | 4500 | |

W | mm | 1110 | 1200 | 2100 | 2100 | 2100 | 2100 | 2100 | ||

H | mm | 2110 | 2200 | 2000 | 2300 | 2200 | 2100 | 2100 | ||

Weight | kg | 1330 | 1680 | 1850 | 1960 | 3320 | 3420 | 3460 | ||

Model | KDCS | KDCS | KDCS | KDCS | KDCS | KDCS | KDCS | |||

Power supply voltage | 3Φ-50Hz-380V | |||||||||

cooling capacity | kW | 433.0 | 539.0 | 581.0 | 718.0 | 762.0 | 1088.0 | 1156.0 | ||

kcal/h | 372,380 | 463,540 | 499,660 | 617,480 | 655,320 | 930,680 | 994,160 | |||

Input power | kW | 141.5 | 167.8 | 181.7 | 197.6 | 227.6 | 287.4 | 325.4 | ||

Chilled fluid flow | m3/h | 76.0 | 89.0 | 98.0 | 121.2 | 134.1 | 176.5 | 231.8 | ||

Compressor | Type | Semi-Hermetic screw type | ||||||||

Start-up mode | 0,25,50,75,100 | |||||||||

Power(kW) | 128.3 | 154.6 | 168.5 | 180.0 | 210.0 | 261.0 | 299.0 | |||

Refrigerant | Type | R-22 | ||||||||

Control mode | Thermostatic Expansion valve | |||||||||

Filling amount(kg) | 79.0 | 89.0 | 98.0 | 118.0 | 160.0 | 176.0 | 199.0 | |||

Evaporator | Type | Shell and Tube | ||||||||

Pipe | B | PT 5" | PT 6" | PT8" | ||||||

Condenser | Type | High-efficient air-cooled inner threaded copper-tubing aluminum fin type | ||||||||

Cooling fan | Type | Low noise outer rotor fan | ||||||||

Air volume(CMM) | 2850 | 2850 | 2850 | 3800 | 3800 | 5590 | 5590 | |||

Power(kW) | 1.1*12 | 1.1*12 | 1.1*12 | 1.1*16 | 1.1*16 | 1.1*24 | 1.1*24 | |||

Protective device | Compressor overheating, over current, high and low pressure, over temperature, flow switch, phase sequence,phase-missing, exhaust overheating,anti-freezing protection. | |||||||||

Dimension | L | mm | 4500 | 6100 | 8800 | 8800 | 9010 | 13380 | 13380 | |

W | mm | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | 2100 | ||

H | mm | 2300 | 2200 | 2200 | 2200 | 2200 | 2200 | 2200 | ||

Weight | kg | 4950 | 5085 | 5220 | 6980 | 7100 | 10180 | 11200 | ||

Note: 1. Parameters of the above specifications: Inlet/outlet chilled fluid temperature:12℃/7℃ Outdoor ambient temperature DB35℃/WB24℃ | ||||||||||

2. The above specifications are subject to change without notice, if there are special requirements, please ask for specifications before ordering | ||||||||||

Actual KDCS series photos shot in our factory:

|  |

|  |

Our main product:

Chiller, Freezer, TCU, Screw Chiller, Low-temperature freezer, chiller, heat recovery unit, environmental chiller, laser chiller, cold oil machine, mold temperature chiller, low-temperature freezer, plant central air conditioning projects, and so on so forth.

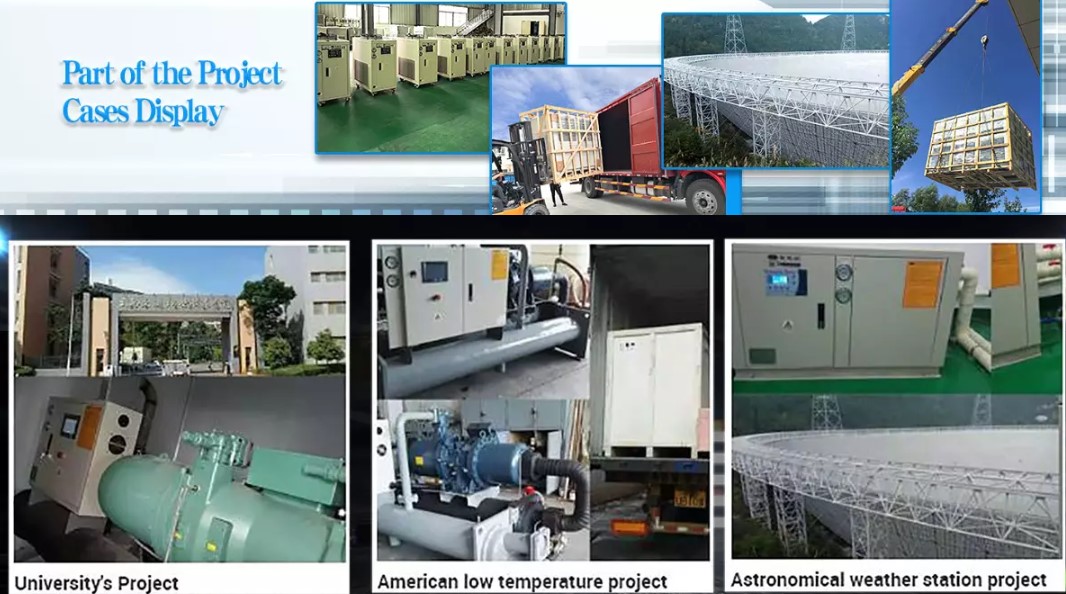

Some projects show:

Kaydeli located in shenzhen and dongguan city, welcomed to visit us!

Kaydeli industrial Park

Kaydeli open China factory in 2002.

With rapid development, Kaydeli establish 2 factory bases located in: Shenzhen city &Dongguan city now.

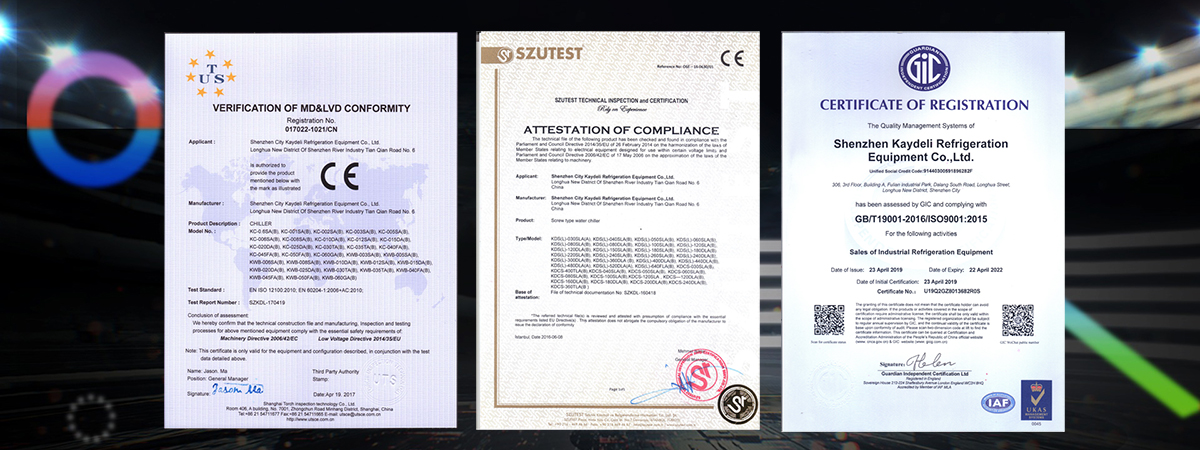

Certification: ISO9001:2016, SGS,Interk auditted factory, CE Certification,China Quality Brand, GTS,

ilac-MRA, CNAS, CMA testing report, 5A after-sales service certification.

Due to healthy development,Kaydeli Brand Chiller Is Top 10 in China Water Cooling Industry Now.

Exhibition:

Core Advantage:

Shenzhen Kaydeli Refrigeration Equipment Co., Ltd. was established in Shenzhen, due to business development, we establish manufacturing base in Dongguan city, which we has two factories to do production and researching now. We mainly manufacture and research chillers, TCU, screw chillers, low-temperature freezer, and has experiences in manufacturing high-end chiller equipment. We operate the brand of “Kaydeli”. We are the only Company with China's well-known trademarks, China top brands and China export branded enterprises of refrigeration industry in China. Our refrigeration technology is well-known in China, we can customize various types of models (from temperature -180℃ to -5℃). Our company has ISO international quality system certification, products have CE (PED) certification, and obtained many patents for energy-saving products.

Certification:

Service Principle: Everything for the user, quick response

Kaydeli is dedicated to providing the following services to our customers:

1. Provide telephone consult for chiller’s performance and technical parameters, online consultation;

2. Provide a complete refrigeration solution or product selection for your production process;

3. Provide other supporting facilities required for refrigeration equipment;

4. Provide financial estimates for refrigeration systems and economic analysis of refrigeration systems;

5. Provide solutions for the freezing station, central air conditioning, combined cold storage project;

6. Provide design plans for cooling which do advanced process design or construction drawing design ;

7. Provide instructions when you are in the process of using the product;

8. Provide the latest developments of the product;

9. Provide installation and commissioning service or guidance;

10. Provide automatic control equipment for refrigeration or cooling systems, also contract to total control cooling equipments;

11. Design and manufacture refrigeration equipment or devices according to your requirements, or jointly develop special refrigeration equipment or devices;

12. Repair and maintenance during the use of the equipment, also contract to overhaul the equipment;

13. Track the production condition of your order.

FAQ:

Q1. Do you have any MOQ limit for chiller?

A: Low MOQ, 1pc for sample checking is available.

Q2. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea, we could ship the standard chiller in 3-15 days, customized chiller in 25-35working days.

Q3. Do you offer guarantee for the products?

A: Yeas, we offer 12 months warranty to our products.

Q4: Where the application?

A: Our products have been widely used in many industries, like Plastic machinery,PCB Machinery, New Energy industry,Pharmaceutical Industry, Petrochemical industry, Environmental protection industry and other industries.

Q5: Are your products can be customized?

A: Yes. Also welcomed to customized non-standard products, can achieve to -180 degree Celsius and EXDIIBT4 Explosion-proof chiller.

Q6: Whats your payment term?

A: International term-30% deposit for production, 70% balance before shipment.

By continuing to use the site you agree to our privacy policy Terms and Conditions.